| SD-WAN improves manufacturing efficiency by optimising network performance, reducing downtime and enhancing security. |

Arguably the greatest determinant for how successful a manufacturer can be, is their optimisation of operational efficiencies. Improving operational processes leads to greater speeds, reductions in workforce requirements and, ultimately, increased profits for the business. One less obvious way of improving the efficiency of operations is to improve network performance, as with an improved network comes better optimised network-reliant operations.

Enhancing Operational Efficiency with SD-WAN for Manufacturing

In this article, we explore how SD-WAN can address your business network inefficiencies, enables the streamlining of operations, reduces costs and also improves overall productivity.

Table of Contents

Manufacturing-Specific Network Challenges

Whilst manufacturers typically look to improve production efficiency across all their individual production line components, they tend to forget about the larger scope. Common network issues can have a huge effect on operational efficiency and production lines due to the latency and disruption that a poor network can create.

Latency is the delay in network transmissions from source to reach the target destination, which for manufacturers can mean delays in production which results in a loss of productivity. Any increase in latency can directly cause an increase in costs and reduction of efficiency, whilst causing bottlenecks for production across multiple machines, sensors and control systems. Due to real-time communications being pivotal for most manufacturers, optimising network efficiency is critical for automated assembly lines with precise timings and coordination.

Unlike latency, which is often seen as a short-term delay, disruptions are typically longer-term and can more often cause entire communication outages. Causes of disruptions can be interference from heavy machinery, equipment failure, power outage or large-scale network congestion. When network connections grind to a halt, so do production lines and this unplanned downtime decreased productivity and has the potential to impact both product quality and customer satisfaction.

But for many manufacturers, changing the network doesn’t come into question as the integration of legacy systems with new, complex networks is daunting. Many manufacturers rely on their older, proprietary systems which are not designed to integrate with new technologies and, whilst these can often have limited compatibility, the lack of interoperability can often be mitigated with technologies such as Software Defined Wide Area Network (SD-WAN) solutions, as this can enable innovations such as Industry 4.0, Internet of Things (IoT) and big data analytics.

Centralised Network Management

One of the key benefits of SD-WAN is its centralised network management, which offers a single pane for deploying, configuring and managing the entire network. This feature can be considered beneficial to manufacturers, as when harnessed, it can reduce the complexity of managing multiple production lines, reduces the requirement for on-site network resources and increases network efficiency.

As manufacturers only require network administrators to manage a single platform, admin teams can manage all production lines in unison with a single update push, reducing the need for individual factory WAN networks to be manually configured. This is particularly beneficial as it not only reduces operational costs but it also allows greater agility to meet production demands and also reduces the risk of human error where individual networks may previously have been manually misconfigured.

Centralised management also enables full visibility into network traffic, with enhanced analytics and reporting allowing network administrator teams to identify issues or underperforming links. For SD-WAN solutions offering granular reporting functionality, SD-WAN can assist manufacturers in finding inefficient resource utilisations, which helps in the process of improving network performance.

For more novice network administration teams, improving network performance and reducing inefficiencies can be a rather daunting task, however SD-WAN has this covered. SD-WAN automates many of the network management processes, dynamically responding to changing network conditions and minimising the need for manual intervention. This reduces the workload for network administrators, whilst also reducing the need for trained on-site staff to handle network management, meaning that businesses can save costs through a reduced administrator workforce.

Optimising Data Transfer and Communication

Production lines often require real-time communications for sensors, coordination and report mechanisms, which SD-WAN can contribute to by optimising data transfer. SD-WAN can leverage multiple transport links, such as multiple dedicated network paths for each production line, enabling communications to be sent over the best performing network path. This optimisation enables seamless real-time communications and collaboration between production lines and gives IT decision makers the opportunity to leverage multiple SLA-backed lines at once.

Manufacturers also depend on their networks being reliable and with SD-WAN businesses can optimise transfer speeds and protect their network from downtime. As traditional WAN is often affected by bandwidth limitations, latency and slow transfer speeds, businesses should consider SD-WAN for its optimised speeds and increased reliability. An example of its benefits is that, by leveraging TCP acceleration and data reduction, SD-WAN enables the transfer of large engineering CAD files between remote sites to be optimised.

Real-time communications can utilise SD-WAN solutions path conditioning and tunnel bonding capabilities, which rebuild lost packets at the destination and both virtualise and aggregate links. This enables real-time applications to operate smoothly without jitter or packet loss, which means that critical production applications can seamlessly communicate.

Application Performance and Traffic Prioritisation

SD-WAN offers Application-Aware Routing (AAR) and application traffic prioritisation, enabling multiple traffic types to be identify and classified based on different protocols, port or through deep packet inspection. This functionality gives SD-WAN a granular understanding of applications on the network and once identified and combined with Quality of Service (QoS) prioritisation policies, ensuring that real-time machine-to-machine communications are given the top priority. This means that businesses-critical applications receive the necessary resources to ensure productivity is maximised, whilst less time-sensitive process, such as backups, are assigned a lower priority.

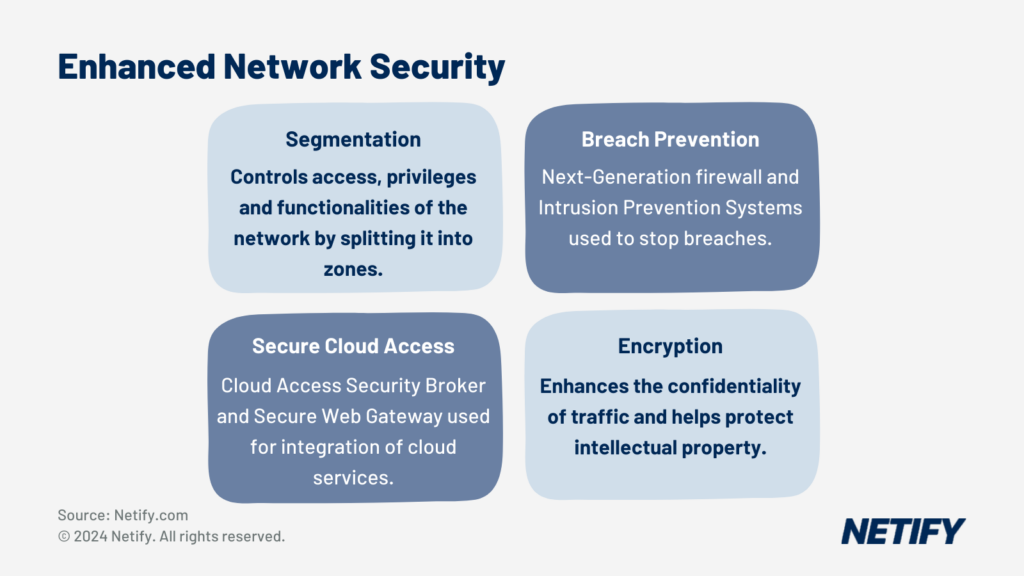

Enhanced Network Security

Enhanced Network Security with SD-WAN

One of the more pressing network considerations for manufacturers is regulatory compliance, which comes with many security requirements and expectations. SD-WAN handles this in various ways, such as segmentation, which applies policies to control access, privilege and functionalities for specific zones of the network. Segmentation is essential for enabling innovations such as Internet of Things (IoT), the integration of sensors and analysis components, that run on hardware incapable of running its own security functions. SD-WAN therefore automatically places IoT devices into restricted segments within the network, isolating these security-lacking devices from other networked processes, protecting them from attack. As logical separation of industrial systems from enterprise networks is mandated by the Industrial Control Systems (ICS) for ISA/IEC62443, the segmentation capability offered by SD-WAN is a key improvement over traditional WAN networks.

SD-WAN isn’t only limited to segmentation though and often comes with features such as Next-Generation-Firewall (NGFW) and Intrusion Prevention Systems (IPS) for protecting against breaches, Cloud Access Security Broker (CASB) and Secure Web Gateway (SWG) for secure integrations of cloud service utilisation and IPsec and AES for encrypted data transfer, improving confidentiality and protecting business intellectual property. This means that SD-WAN enables compliance via industry standards and regulations, encryption and tunnelling for data protection requirements like NIST 800-53 and NIST 800-82 for ICS.

Reducing Downtime and Improving Resilience

Disruptions to production can be detrimental to manufacturers, emphasising the importance of minimising potential network downtime. SD-WAN addresses this issue through failover and redundancy methods, which detect outages or underperforming network links and seamlessly switch to a failover path to ensure data flow. By minimising network downtime, SD-WAN ensures that critical manufacturing systems and applications remain accessible and operational. This is particularly important given the high costs associated with downtime in manufacturing. According to reports, 91% of mid-sized and large enterprises lose $300,000 from just an hour of network outages.

Reduction in downtime is achieved by utilising dynamic path selection, which assesses the quality of WAN links based on factors such as latency, packet loss and bandwidth. By minimising disruptions, manufacturers can maintain high levels of productivity and efficiency on the factory floor.

For manufacturers utilising innovations such as Industry 4.0, IoT and smart manufacturing, there is an even greater reliance on connectivity as these technologies depend on the collection and analysis of data from machines and processes. By reducing network downtime, manufacturers can keep these smart processes flowing.

Case Studies and Real-World Applications

A medium-sized industrial manufacturing company deployed Aryaka’s SD-WAN solution and experienced improved application performance, which resulted in greater manufacturing productivity. The SD-WAN solution also reduced total cost of ownership (TCO), providing the business with the benefit of less expenditure whilst improving their profits. This meant that the company was able to transform its network to solve the issues they experienced with performance of global applications.

A global automotive manufacturer deployed SD-WAN across its production sites and experienced significant reductions in network downtime, which led to improved productivity. The SD-WAN solution enabled the manufacturer to optimise processes, minimise disruptions, and leverage Industry 4.0 technologies, which gave them a competitive advantage over other manufacturers in the industry.

Future Outlook

SD-WAN is set to continue improving as a network solution for manufacturers. The convergence of SD-WAN and Secure Access Service Edge (SASE) has provided networks with a range of new features such as Zero Trust Network Access (ZTNA), Firewall-as-a-Service (FWaaS) and Cloud Access Security Broker (CASB), enabling businesses to utilise a greater range of network edges, whilst providing data protection and ensuring regulatory compliance. This means that manufacturers can better utilise the cloud, with applications such as CAD becoming increasingly cloud-delivered via Software-as-a-Service (SaaS), which enables greater flexibility with both remote and distributed workforces.

Future Proofing With SD-WAN

SD-WAN solutions are also integrating Artificial Intelligence (AI) and Machine Learning (ML) to provide the ability to optimise networks in real-time based on current analytics and telemetry, which can play a key role in proactive problem resolution. These methods can prevent issues before they can take effect, actioning resolutions far faster than human administrators typically can, which further minimises downtime and provides the network in even greater operational efficiency.

Conclusion

SD-WAN offers a significant upgrade for manufacturers over their traditional WAN networks as it has the ability to address critical network inefficiencies and enhance operational efficiencies. By improving network performance, manufacturers can reduce latency, minimise disruptions, and ensure real-time communication, which are essential for automated assembly lines and precision operations. SD-WAN offers features such as centralised management, which simplifies the process of managing multiple product lines and offers security features for enabling Industry 4.0 and Internet of Things sensors and devices. This gives the network greater capabilities, reduced operational costs and enhanced agility. These features, along with the security offerings of SD-WAN which assist businesses with meeting regulatory compliance, make SD-WAN an invaluable tool for improving productivity and gaining a competitive edge.