| SD-WAN enhances factory automation by improving network reliability, reducing latency, and securing real-time communication between machines and sensors. |

Since their inception, manufacturers have striven to automate their factories wherever possible, improving the efficiency, productivity and quality of production lines. Whilst in the early 1800s automation came from punched cards, used for complex pattern weaving, in the modern-day manufacturers are equipped with a vast array of computerised production line machinery. These systems are increasing being interconnected, allowing streamlined communications and enabling both reliable and holistic automation of production.

Achieving this interconnectivity can be quite the struggle, with manufacturers finding that many systems are incompatible, the volume of traffic is too large or maintaining the network is simply too difficult. However, these issues are mitigated by Software Defined Wide Area Network (SD-WAN) solutions, which offer a vast improvement on traditional WAN offerings.

In this article, we explore how SD-WAN can play a key supporting role in factory automations and how manufacturers can leverage its growing number of features to improve the efficiency, security and reliability of the network, whilst also being adaptable to meet the future trends of manufacturing automations.

Table of Contents

Future Trends in Manufacturing Automation

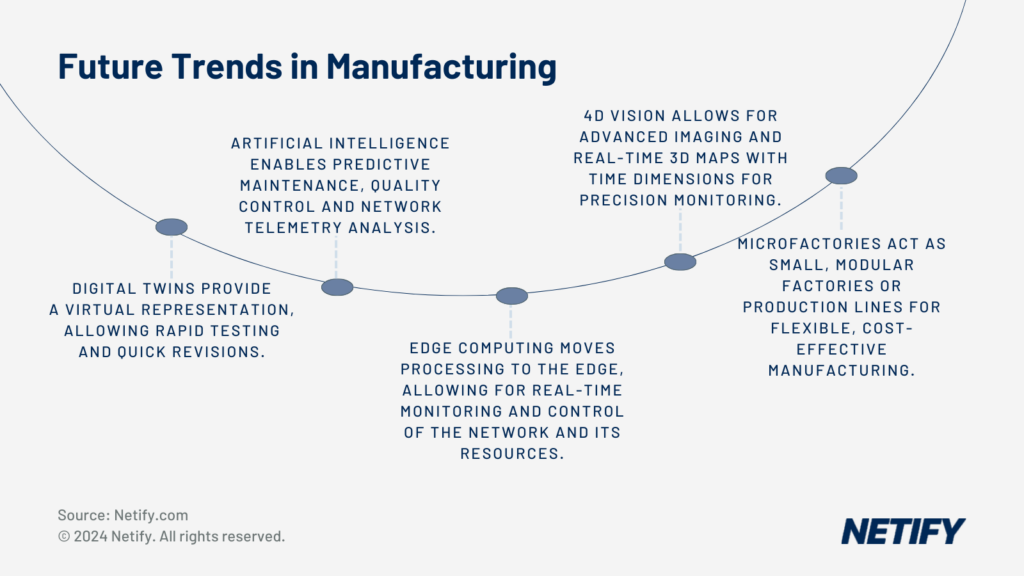

There are many key trends that manufacturers are utilising to improve automation, which include technologies such as digital twins, artificial intelligence (AI), edge computing and 4D vision. These technologies offer many ways to improve efficiency and productivity, such as digital twins which provide a virtual representation, accurately reflecting a physical object and enabling manufacturers to conduct rapid testing and make quick revisions, without having to produce the physical item.

Edge computing has become a significant factor for network management when utilising manufacturing automation technologies such as Internet of Things (IoT) and 4D vision, 4D Vision in IoT primarily involves advanced imaging technologies such as LiDAR (Light Detection and Ranging), which enables the creation of detailed, real-time 3D maps augmented with an additional dimension of time to provide dynamic, real-time updates. In manufacturing, 4D Vision is integrated with IoT devices to provide precise, real-time monitoring and control of production lines. For instance, SiLC Technologies’ Eyeonic Vision Sensor uses FMCW (Frequency Modulated Continuous Wave) LiDAR technology to offer high-resolution imaging that can identify and analyse materials and surfaces, even in challenging environmental conditions. This level of detail supports more effective automation and quality control on the production line, reducing downtime and improving product consistency.

Another key trend within manufacturing automations is the emergence of microfactories. These are small, modular factories or production lines that offer businesses the flexibility to make changes on the fly, reduce the number of modules to save cost or swap specific modules for greater maintainability. Each of these benefits not only improves business agility to move resources and adapt production to meet demands but also promotes a sustainable approach to manufacturing, by reducing waste following factory or production line decommissioning, as these modules can be used elsewhere. For businesses looking to attain carbon neutrality, microfactories are a potential solution.

Future Trends within the Manufacturing Sector

Key Challenges in Manufacturing Automation

Unfortunately, as manufacturers look to integrate many of these automation techniques, they can often meet challenges that prevent them. The most common of these is incompatible integrations, where new and existing systems cannot be directly connected without a huge workaround, something that many manufacturers aren’t willing to commit to. One example of these integrations being incompatible is through manufacturer’s networks being unable to integrate all production systems. Whilst this may not be possible with traditional WAN networks, SD-WAN can support a vast array of technologies, often across multiple vendors, enabling manufacturers to connect systems and tailor their network to fit their unique requirements.

Another key challenge faced by manufacturers is data management, a core component for meeting ISA/IEC62443, which mandates the logical separation of industrial systems from enterprise networks. This is due to integrations such as Internet of Things (IoT) sensors and devices sending vast amounts of data, which can cause bottlenecks, network outages and latency for critical traffic. To mitigate this, the segmentation capability offered by SD-WAN is a key improvement over traditional WAN networks and applies policies to control access, privilege and functionalities for specific zones of the network and provides a logical separation to management data on the network. This enables machines and sensors to have their data processed and analysed in real-time, without fear of interrupting communications between production line machines.

Finally, cybersecurity is a critical concern for manufacturers, which is only increased with a connected set of systems. With greater connectivity comes greater risk of security threats breaching production systems and typically this has left manufacturers either integrating a complexity set of security appliances or leaving production machines unconnected, as offline systems adds a layer of protection for the system. As manufacturers move towards a connection factory for automation purposes, protecting against espionage and threats is of utmost importance to maintain continuous production and security of sensitive data such as intellectual property. Security features are in fact built into SD-WAN solutions, offering networks with pre-setup integrations that reduce reliance on traditional appliances and minimises the complexity of adding security to your manufacturing network.

Role of AI in Manufacturing

The role of AI in Manufacturing

One of the most talked about technologies at current is Artificial Intelligence and, to no surprise, has also entered the field of manufacturing. Manufacturers are leveraging AI automation for predictive maintenance and quality control mechanisms, due to AI (and Machine Learning) algorithms being capable of analysing huge volumes on data, equipment telemetry both present and historical, enabling highly accurate scheduling of maintenance ahead of potential failures.

The quality control mechanisms reduce the need for human input, detecting production quality and determining how improvements can be made. This, along with quality control mechanisms, help keep production lines flowing, reducing disruptions and maximising output for improved profits.

However, that’s not all, as AI can also be leveraged to analyse network telemetry and machine data to provide cohesive reports, which help manufacturers to strategically optimise production processes, allocate resources to specific lines and improve overall operational efficiency.

How SD-WAN Enhances Factory Automation

SD-WAN offers a reliable, flexible and secure network infrastructure, which in turn provides many benefits over traditional WAN networks. By improving network reliability and performance, manufacturers can synchronise real-time systems to communicate data between sensors and machines. Through this real-time connection, manufacturers can create seamless automated operations, with systems that can rapidly respond to changes in environment.

Through the ability of SD-WAN to support edge computing techniques, manufacturers can leverage localised processing of data, which reduces network traffic load and latency faced by critical traffic. This is important for businesses looking to utilise Internet of Things devices, such as for robotics or machine vision use cases, as these are heavily reliant on real-time connections and small delays can severely impact performance.

Whilst edge computing reduces the volume of traffic on the network, manufacturers may still be concerned about the communication traffic, which is critical to business operations, experiencing degradation. Dynamic and adaptive traffic management has become a necessity to avoid degradation and SD-WAN assists with this through Quality of Service (QoS) policies, which enable prioritisation of automation data and communications between machines and control systems.

To improve automation efficiencies, manufacturers can utilise the monitoring functionality offered by SD-WAN. SD-WAN can monitor and control factory operations through real-time data visibility, telemetry and analysis of network performance. This enables manufacturers to be flexible, reconfiguring the network to support changes in demands, scale production lines and reach peak efficiency without having any major network overhauls.

For manufacturers concerned about the confidentiality and integrity of their production lines and intellectual property, SD-WAN also integrates vast security feature and to reduce the complexity of setting up lots of security appliances, SD-WAN provides advanced security features pre-packaged. These can often include features such as next-generation firewalls (NGFW) and intrusion prevention systems (IPS). These security features are just some of many that ensure the protection of the network, ensuring that no breach of the system occurs. Other advanced security features include the use of Artificial Intelligence (AI) and Machine Learning (ML) for anomaly detection. These indicate potential threats to the network and, by allowing for proactive mitigation, SD-WAN enables administrators to rapidly respond to network threats.

Case Studies and Applications

One example of a manufacturer moving to SD-WAN is that a mid-size manufacturing company, facing frequent system downtimes and productivity losses, integrated SD-WAN to streamline its production line operations. Integrating Cisco Meraki SD-WAN, it enabled the manufacturer to connect IoT devices on the production line to a stable, scalable network. This integration ensured reliable data transmission from sensors and machines, enabling real-time monitoring and control of production processes. This upgrade allowed the company to automate its production line, improve product quality, and focus on growth rather than network management.

Similarly, another manufacturer wanting to integrate IoT, utilised Peplink’s SD-WAN solution helped address these issues by providing a reliable, high-speed network capable of managing the data traffic from numerous IoT devices. This implementation not only improved the efficiency and reliability of the production line but also enhanced the overall operational productivity by reducing downtime and optimising network performance. Peplink’s SD-WAN technology allowed the company to streamline their IoT device management and achieve better scalability and security across their manufacturing sites.

Conclusion

As manufacturing processes continue to be automated, manufacturers should consider the benefits of implementing an SD-WAN architecture for networking their production lines and connecting processes to enhance network reliability, reduce latency and support edge computing. SD-WAN ensures seamless communication between sensors and machines, which is crucial for real-time operations. The built-in security features address the any security concerns for the network, whilst providing manufacturers with a secure environment to protect sensitive data and intellectual property. Finally, the ability to manage vast amounts of data efficiently and the capability to leverage AI and edge computing for the automation of many tasks, both on the network and on the production line.